|

|

|

Batch Oven Features & Benefits

• Heavy duty construction

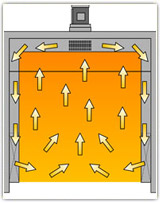

• Uniform air distribution along the entire length of the work chamber provides quality cured finishes and optimum cure cycles (see figure 1)

• Better Temperature Uniformity - provides consistent, high quality curing results...part after part!

• Quicker Heating - cures more parts every day!

• Motorized (modulating) gas control valve

• Digitally Temp. Controller cum indicator

• No Powder Blow-Off - reduces rework

• Tunnel Type Batch Oven for operating/using 2 nos. trolleys simultaneously.

CONSTRUCTION

Oven is double walled and fabricated on angle iron structure and properly reinforced, wherever is necessary. Outer and inner made of thick mild steel sheet and outer surface painted with silver gray hammer tone and inner surface with high temperature aluminum paint.

Rock- wool slap (Insulation) of density 96 kg/m is used between the two walls of oven. This insulation is of sandwich type having male Female joint to minimize the air leakage. Insulation 100mm.

AIR CIRCULATION

Forced Air circulation is provided with suitable fan in the inner working space and the fan driven by a ‘V’ belt with the help f Motor of suitable capacity. ‘V’ Belt Motor and bracket with bearing are fixed outside the chamber for easy servicing and oiling as when required. Air is blown over the heating elements that are provided on both sides & the hot air after passing through the inner chamber.

TEMPERATURE CONTROL

Digital Thermostat / Digital temperature Indicator cum controller with variable setting coarse and fine with display fitted on to the control panel.

• Heavy duty construction

• Uniform air distribution along the entire length of the work chamber provides quality cured finishes and optimum cure cycles (see figure 1)

• Better Temperature Uniformity - provides consistent, high quality curing results...part after part!

• Quicker Heating - cures more parts every day!

• Motorized (modulating) gas control valve

• Digitally Temp. Controller cum indicator

• No Powder Blow-Off - reduces rework

• Tunnel Type Batch Oven for operating/using 2 nos. trolleys simultaneously.

CONSTRUCTION

Oven is double walled and fabricated on angle iron structure and properly reinforced, wherever is necessary. Outer and inner made of thick mild steel sheet and outer surface painted with silver gray hammer tone and inner surface with high temperature aluminum paint.

Rock- wool slap (Insulation) of density 96 kg/m is used between the two walls of oven. This insulation is of sandwich type having male Female joint to minimize the air leakage. Insulation 100mm.

AIR CIRCULATION

Forced Air circulation is provided with suitable fan in the inner working space and the fan driven by a ‘V’ belt with the help f Motor of suitable capacity. ‘V’ Belt Motor and bracket with bearing are fixed outside the chamber for easy servicing and oiling as when required. Air is blown over the heating elements that are provided on both sides & the hot air after passing through the inner chamber.

TEMPERATURE CONTROL

Digital Thermostat / Digital temperature Indicator cum controller with variable setting coarse and fine with display fitted on to the control panel.